PA6CF30NC is a Polyamide 6 material reinforced with 30% carbon fiber, offering outstanding mechanical properties and heat resistance. Features include high tensile strength, superior impact resistance, and a UL HB flame retardant rating. Suitable for various applications such as automotive components, industrial machinery, and electrical equipment, it provides cost-effectiveness and environmental sustainability.

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Polyamide 6 Carbon Fiber Reinforced PA6-CF30

LONGZHENG

PA6CF30NC

We are pleased to introduce our premium product, PA6CF30NC, a polyamide 6 material reinforced with 30% carbon fibre. This innovative product is meticulously designed to offer enhanced mechanical properties, making it an ideal choice for various industrial applications where strength, durability, and performance are paramount.

LONGZHENG

PA6CF30NC

PA6-CF30

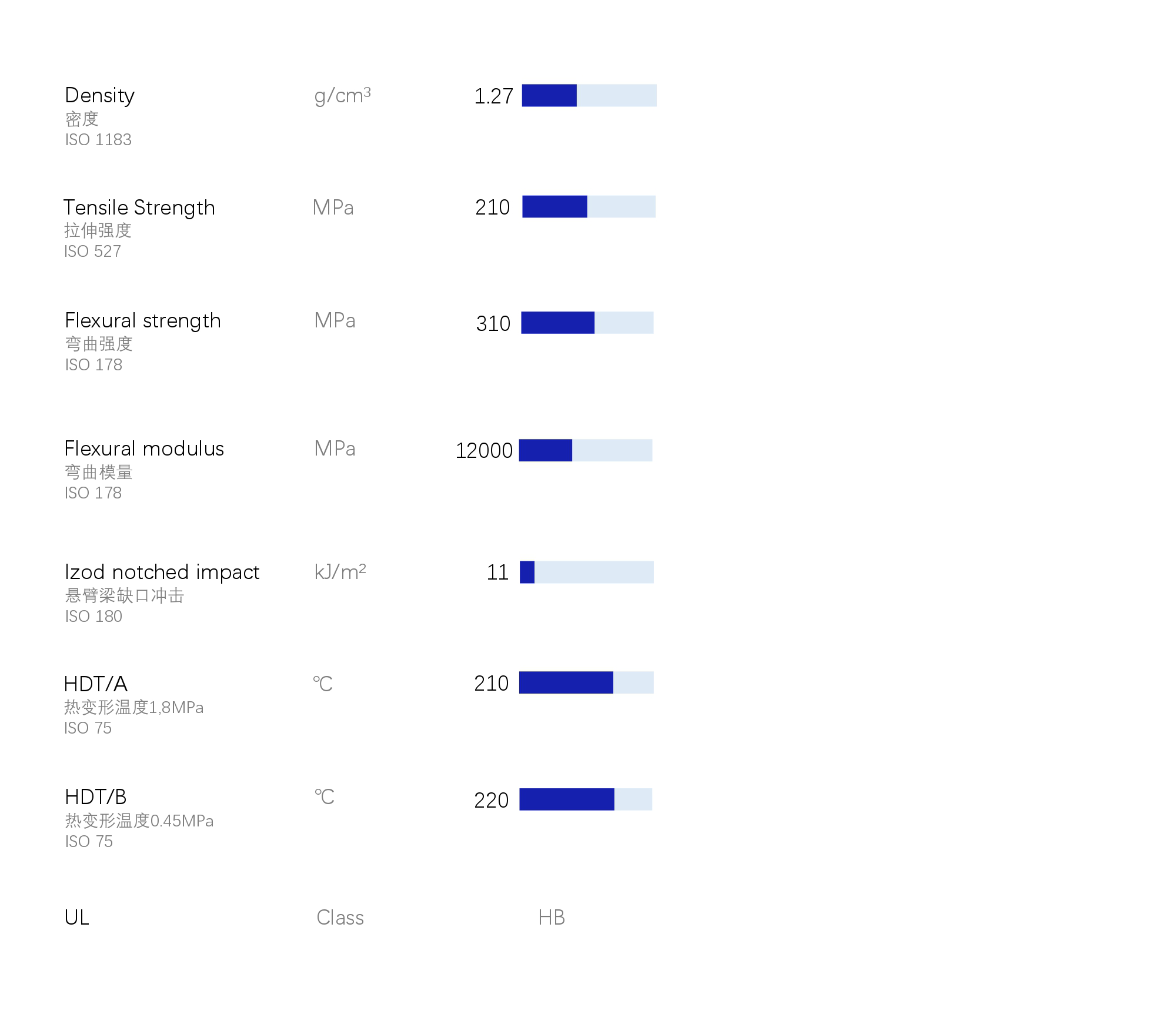

PA6CF30NC Mechanical Properties:

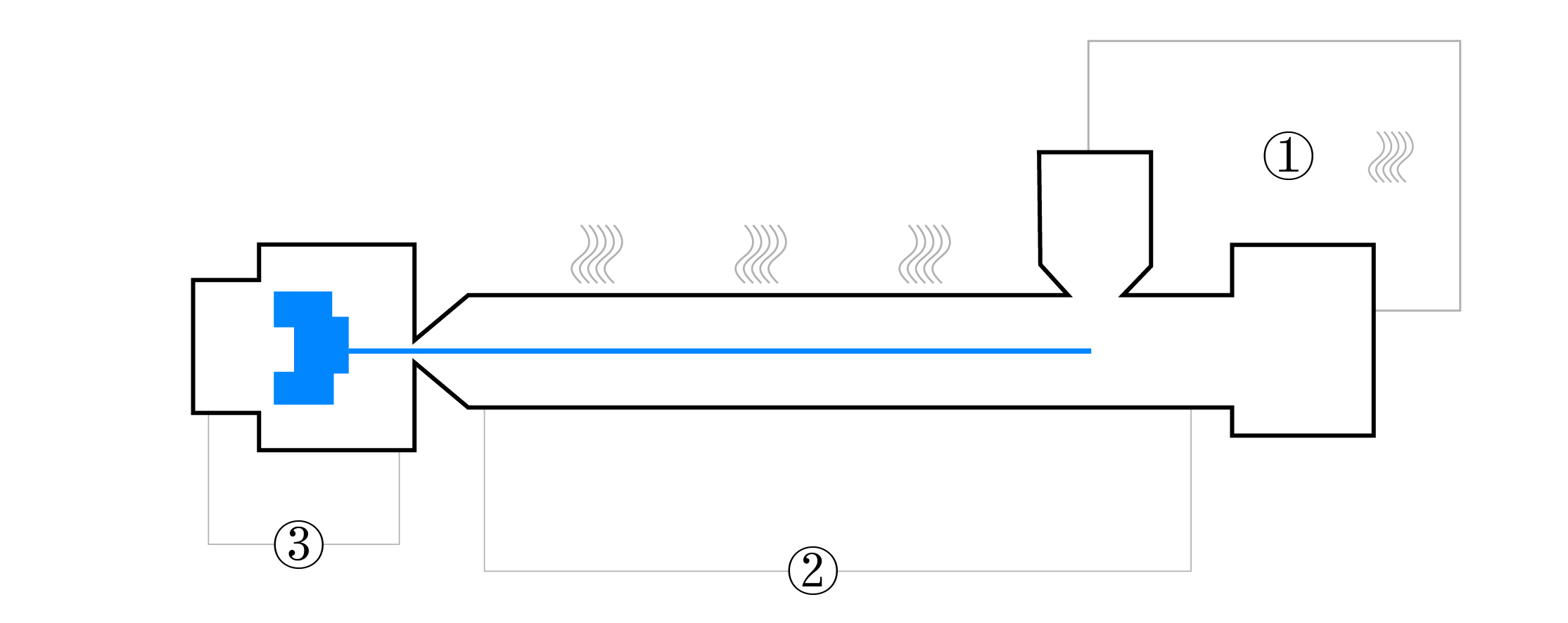

Processing Information:

Attaining the desired mechanical and thermal properties of LONGZHENG PA6CF30NC (PA6-CF30) relies on a precise handling and molding process, which plays a critical role in ensuring optimal product quality.

Product Features and Advantages of the PA6CF30NC

Enhanced Mechanical Properties: The PA6CF30NC offers superior tensile strength, flexural modulus, and flexural strength compared to traditional polyamide materials. This ensures improved performance and longevity in demanding applications.

High Impact Resistance: With an Izod notched impact strength of 11 kJ/m2, our product exhibits excellent resistance to impact and can withstand challenging operating conditions without compromising its structural integrity.

Temperature Resistance: The PA6CF30NC demonstrates remarkable thermal stability with a heat deflection temperature (HDT) of 210°C at 1.8 MPa and 220°C at 0.45 MPa. This makes it suitable for applications requiring resistance to elevated temperatures.

L Classification: Our product meets the HB classification under UL standards, indicating its flame-retardant properties and compliance with safety regulations.

By incorporating PA6CF30NC into your manufacturing processes, you can achieve a balance between performance and cost-effectiveness. Its enhanced mechanical properties may lead to reduced maintenance costs and an increased product lifespan.

In conclusion, the PA6CF30NC stands as a testament to our dedication to innovation, quality, and customer satisfaction. We invite you to explore the possibilities that this exceptional product offers and look forward to forging a successful partnership with you.