Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Please enter the email address you’d like your password reset information sent to.

Email format error

Email cannot be empty

Email does not exist

Reset account password

For the account

6-20 characters(letters plus numbers only)

The password is inconsistent

Reset success

Your password was reset. You can log in using your new password.

Login

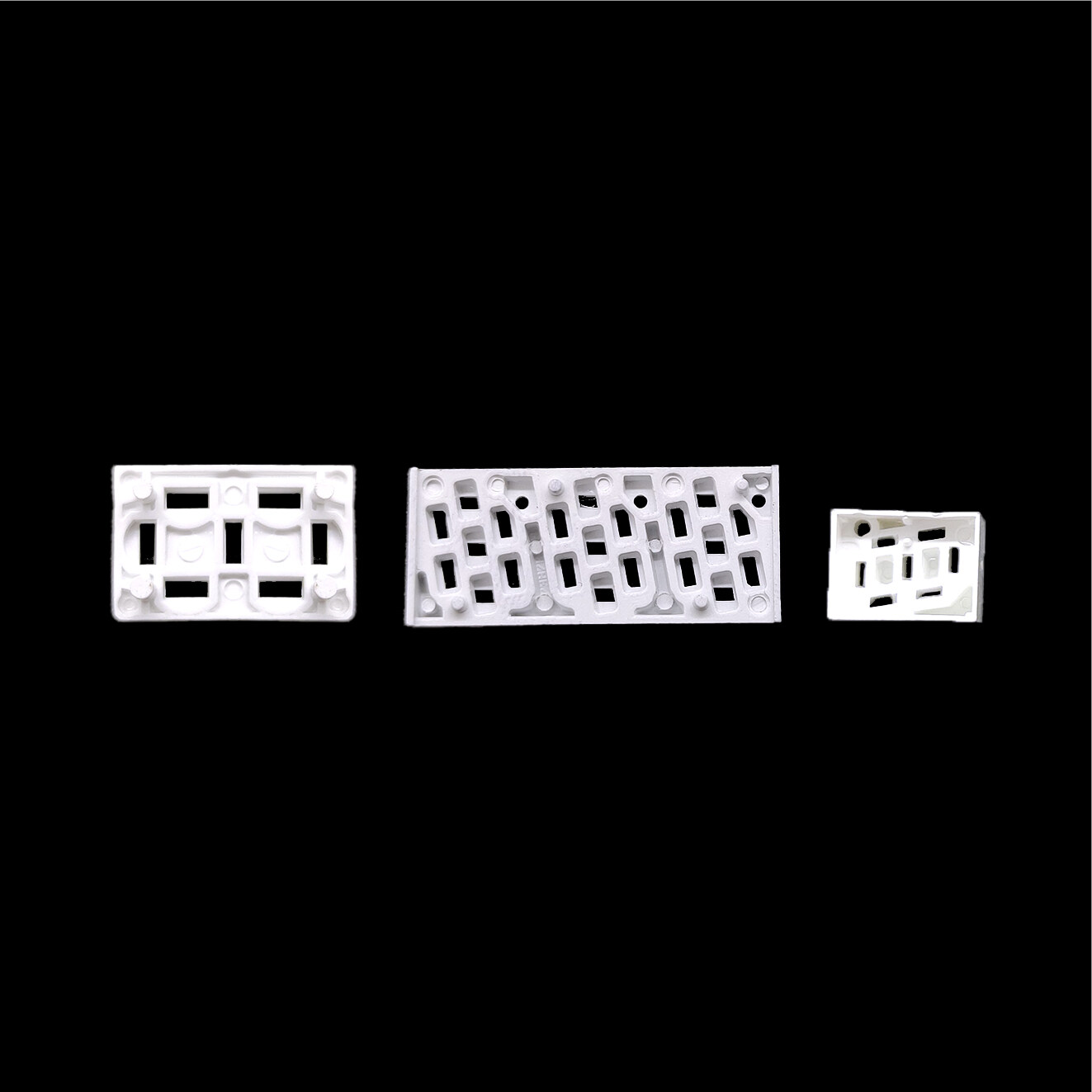

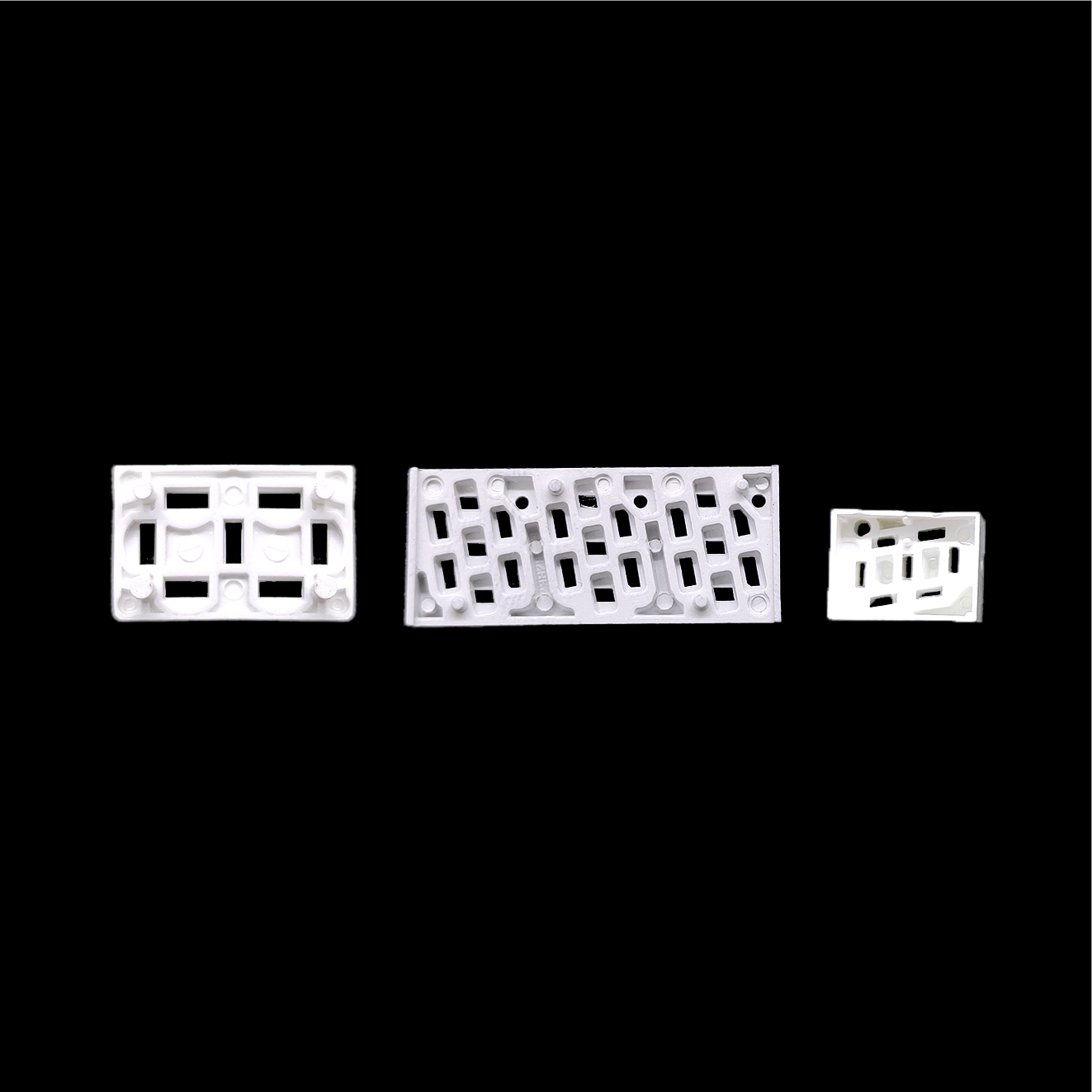

Application case of PPA material-LED digital tube

2024-04-12 15:39:20

Application case of PPA material-LED digital tube

Introduction:

In this blog post, we will explore the application of PPA material in LED digital tubes. PPA material is commonly used in microelectronic components like LEDs to ensure precision and resistance to heat and soldering. With the increasing demand for miniaturization and faster switching operations, the mechanical and thermal dissipation of power supply components is crucial.

PPA Material Application in LED Digital Tubes:

Customers of LED digital display tubes have specific requirements for the performance of the products. They expect that products baked at 135-150℃/2h will not deform or become brittle. The color of the tubes needs to remain stable and not prone to yellowing under high temperatures. Additionally, it is essential that the product will not turn yellow when welded at 270℃/5min. Moreover, the product should not easily transmit light and have light-shielding capabilities.Benefits of PPA Material in LED Digital Tubes:

We will discuss the benefits of using PPA material in LED digital tubes, such as its ability to withstand high temperatures without deformation or yellowing. PPA material also provides excellent mechanical and thermal dissipation properties, making it ideal for applications where precision and reliability are essential.

Challenges and Solutions:

We will address the challenges faced in using PPA material in LED digital tubes, such as ensuring that the product does not transmit light easily and has light-shielding capabilities. We will also explore potential solutions to overcome these challenges and optimize the performance of LED digital tubes.Conclusion:

In conclusion, the application of PPA material in LED digital tubes offers numerous benefits, including resistance to heat, stability in color, and reliable performance under high temperatures. By understanding the specific requirements of customers and addressing challenges effectively, manufacturers can ensure the quality and durability of LED digital tubes for various applications.Contact us